News

News

Why Air Suspension Centrifugal Blowers Are Replacing Traditional Roots Blowers

Post time: 2025-12-24 13:19:35

For many years, Roots blowers have been the “safe choice” for industries like wastewater treatment, aeration, and pneumatic conveying. They are simple, strong, and familiar. But today, rising energy costs, stricter noise rules, and higher maintenance demands are forcing users to look for something better. That’s where air suspension centrifugal blowers come in.

They are not just a new type of blower—they are a smarter upgrade.

From High Energy Use to Real Savings

The hidden cost of traditional Roots blowers

Roots blowers run at constant speed and rely on mechanical contact. This means higher power loss, more heat, and wasted energy—especially in systems that operate 24/7. Over time, electricity bills become one of the biggest operating costs.

A 30%–50% efficiency jump

Air suspension centrifugal blowers change the game. Thanks to advanced aerodynamics and friction-free bearings, they can achieve 30%–50% higher efficiency compared to traditional Roots blowers. Less energy in, more air out. For plants running continuously, the savings are easy to measure—and hard to ignore.

Oil-Free Operation That Actually Means “No Maintenance”

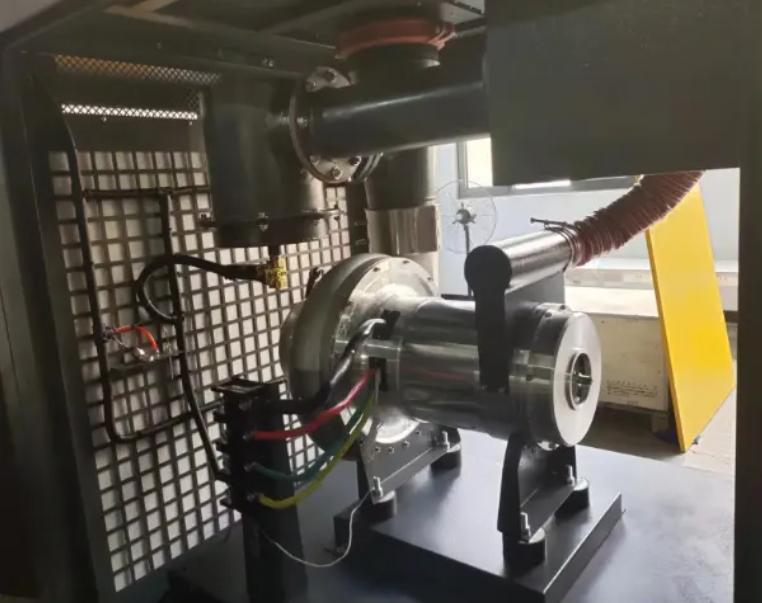

How air suspension bearings work

Instead of oil-lubricated bearings, these blowers use air suspension bearings. When the blower starts, a thin layer of air lifts the shaft, creating zero mechanical contact.

Why this matters in real life

No friction means:

No lubricating oil

No oil filters

No regular bearing maintenance

This is especially important in wastewater treatment and food-related applications, where oil contamination is a serious risk. Fewer service stops also mean higher uptime and lower labor costs.

Variable Frequency for Changing Conditions

Not all systems need full power all the time

Traditional blowers often run at fixed speed, even when demand is low. That’s like driving a car at full throttle in city traffic.

Flexible control from 45% to 100%

Air suspension centrifugal blowers support wide variable frequency operation, typically from 45% to 100%. This allows the blower to match real-time air demand, improving efficiency and protecting the system from unnecessary stress.

Low Noise That Improves the Work Environment

Where does the noise go?

Roots blowers create noise from mechanical contact and air pulsation. In contrast, air suspension centrifugal blowers have no mechanical friction, and their airflow is smooth and continuous.

Below 80 dB at 1 meter

At a distance of 1 meter, average noise levels are below 80 dB. The blower itself does not “create” noise—most sound comes from airflow, which can be easily controlled with proper piping and silencers. This makes them ideal for urban plants and indoor installations.

Smaller Size, Bigger Design Freedom

Compact by design

Air suspension centrifugal blowers are typically 50% smaller than Roots blowers of the same capacity. Integrated motors, bearings, and control systems reduce the overall footprint.

Easier installation and upgrades

A smaller size means:

Less space needed

Easier retrofits

Cleaner, more modern blower rooms

This is a big advantage for plant expansions or replacement projects.

Final Thoughts: A Practical Upgrade, Not Just New Technology

Air suspension centrifugal blowers are not popular just because they are “new.” They are replacing Roots blowers because they solve real problems—high energy use, heavy maintenance, noise, and space limits.

If your system runs long hours and energy cost matters, switching is no longer a future idea. It’s a practical step you can take today.

What matters more to you: lower power bills, less maintenance, or quieter operation?

English ▼

English ▼